In EMC "dropout" means Battery drops to 0V. FMC1278R3 (CI 260) is an example of various combinations of such battery voltage dropouts. The problem is that no automotive battery can really drop its output to 0V for say 5 seconds as well as for 50 ms without to blowout a fuse.

Therefore the only way to simulate correctly a “battery drop to 0V” is to disconnect DUT's B+ line from battery. The test equipment offers such capability to momentarily disconnect the battery during “voltage dropout” simulating a “0V” like condition, practically no current through supply lines to DUT.

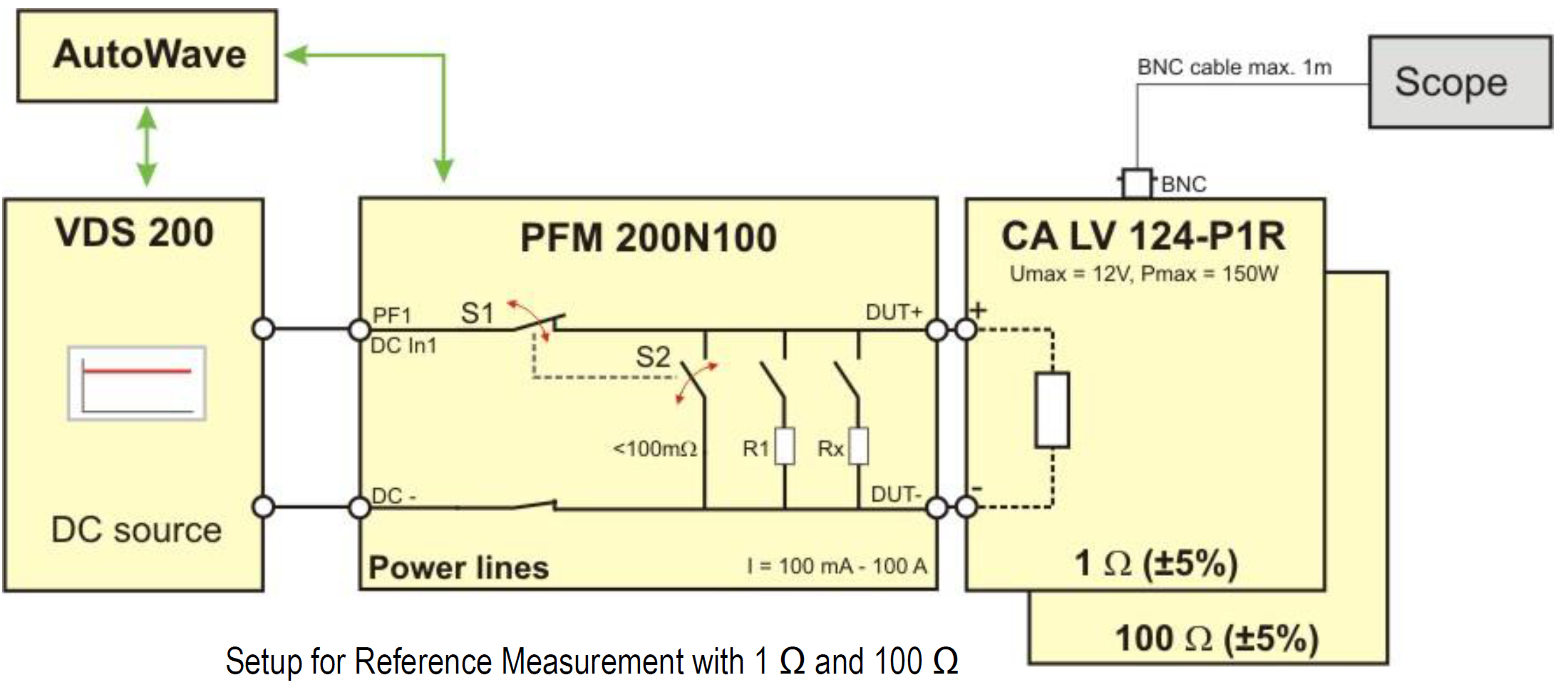

This involves the use of PFM200N + VDS200Q + AutoWave to generate the CI 260 type of pulses. PFM200N acts like a very fast switcher disconnecting its output from DUT. So far only FCA (CS.00054) figure it out to ask “open condition” during “0V” battery voltage dropouts.

In EMC we use the wording “voltage dip” to describe a momentary battery voltage drop (e.g. 4.5V) below minimum supply voltage (e.g. 9V). Obviously in this scenario the Battery B+ line is not disconnected from DUT during the “voltage dip to 4.5V” of 100ms.

Christian Rosu Feb 17, 2021

Test Procedure:

- what the activity is (DUT type)

- who is to perform the activity (EMC Testing Laboratory)

- when the activity is to take place

This is more of an EMC Test Plan Template document that:

- defines the DUT classification and category

- lists required EMC Test Methods defined by the automotive OEM specs or International Standards (ISO, CISPR, SAE, etc.).

Test Method:

- how the actual EMC testing is to be carried out (test equipment configuration)

- defines measurable data format for reporting and acceptable stress level limits

This more of a Work Instruction outlined by automotive OEM EMC specs and international standards.

Christian Rosu, Dec 11, 2020.