20. April 2021 22:08 by Christian in

EMC/EMI, EMC TEST PLAN One common mistake in EMC Test Plans is to associate Pass/Fail criteria with DUT Operating Modes.

For Operating Modes it is critical to define how DUT's:

1) Load Simulator & Support Equipment is configured.

2) Functions are activated.

3) Behavior is monitored.

4) data is collected and reported.

Defining Pass/Fail Criteria for a particular Operating Mode maybe in conflict with requirements listed by automotive OEM EMC spec or standard. The DUT performance and response behavior will always vary depending on the Test Method.

Based on Functional Status Classification the Pass/Fail Criteria must be specified for each Test Method while the DUT is activated in a particular Operating Mode.

For example, ISO 7637-2 Pulse #1 (t2 is 0V for 200 ms). I doubt that an E-Net port won’t miss data packets generating bit errors under such circumstances. Depending on the Test Method and required immunity severity level the EMC spec/standard would allow certain self-recoverable DUT anomalies. Since the EMC Test Plan can override the EMC spec requirement would be a mistake to mention something like "no loss of E-Net data packets" as pass criteria for "DUT Operating Mode #1". This would imply that loosing one packet of data during Pulse #1 the DUT "fails" when in fact the EMC spec would allow it:

"One or more functions of the DUT can go beyond specified tolerance provided that all functions return within normal limits after the exposure is removed (e.g., after UA power is re-applied after the 200 ms defined by t2 as defined in ISO 7637-2). No damage or degradation of memory functions is permitted."

Based on FMC1278R3 and CS.00054:2018 Production Representative Hardware and Software should be used for all verification testing unless approved differently by OEM via EMC Test Plan.

The Production Representative Test Sample is built using production representative hardware and software constructed using production representative processes, tooling, etc.

Following Software Changes in addition to PCB Changes re-validation for test methods like ESD, CISPR 25 RE, BCI, RI ALSE , Hand Portable Transmitters, Transients, Voltage Dips and Dropouts may be required.

FMC require DV testing to be performed using production representative components but not necessarily components constructed from production tooling.

EMC DV1 Testing for PCM (Powertrain Control Module) is normally performed with test software mutually agreed to by FMC D&R, EMC and the supplier.

EMC DV2 Testing for PCM must be completed using Production Intent Hardware and the latest available Application Software.

FCA require DUT Validation Testing done on Production Intent Samples using Production Intent Hardware and Software.

Production Intent Components must be used for the inputs and loads including switches, sensors, pulse width modulated loads, solenoids and motors.

The DC Power Supply should be selected as follows:

Rs (Internal Resistance) < 0.01 OHM DC

Zs (Internal Impedance) = Rs for frequencies < 400 Hz.

Output Voltage:

▶ does not deviate more than 1 V from 0 to maximum load (including inrush current)

▶ recovers 63% of its maximum excursion within 100 ms

Vr (Superimposed Ripple Voltage):

▶ does not exceed 0.2 V peak-to-peak

▶ maximum frequency of 400 Hz

NOTE:

☞ When a battery is used for EMC testing, a charging source is needed to achieve the specified voltage reference levels.

☞ It is important to ensure that the charging source does not affect the test.

☞ Linear Power Supplies are preferable vs Switching Power Supplies.

☞ Prior to CISPR 25 test methods ensure that the RF noise produced by the power supply is at least 6 dB lower than the limits specified in EMC Test Plan.

☞ If the Power Supply is located outside of the EMC test chamber, ensure thzt a bulkhead RF filter is used to prevent RF noise from entering or leaving the shielded enclosure.

☞ If using a HV battery, then it must be contained in a shielded enclosure.

☞ 12V Power Supply Volatge = 13.5 (+0.5/-1.0)V

☞ 24V Power Supply Voltage = 26 (+1.0/-2.0 V

A few remarks on correct Load Simulator configuration for CISPR 25 Conducted Emissions Current test method.

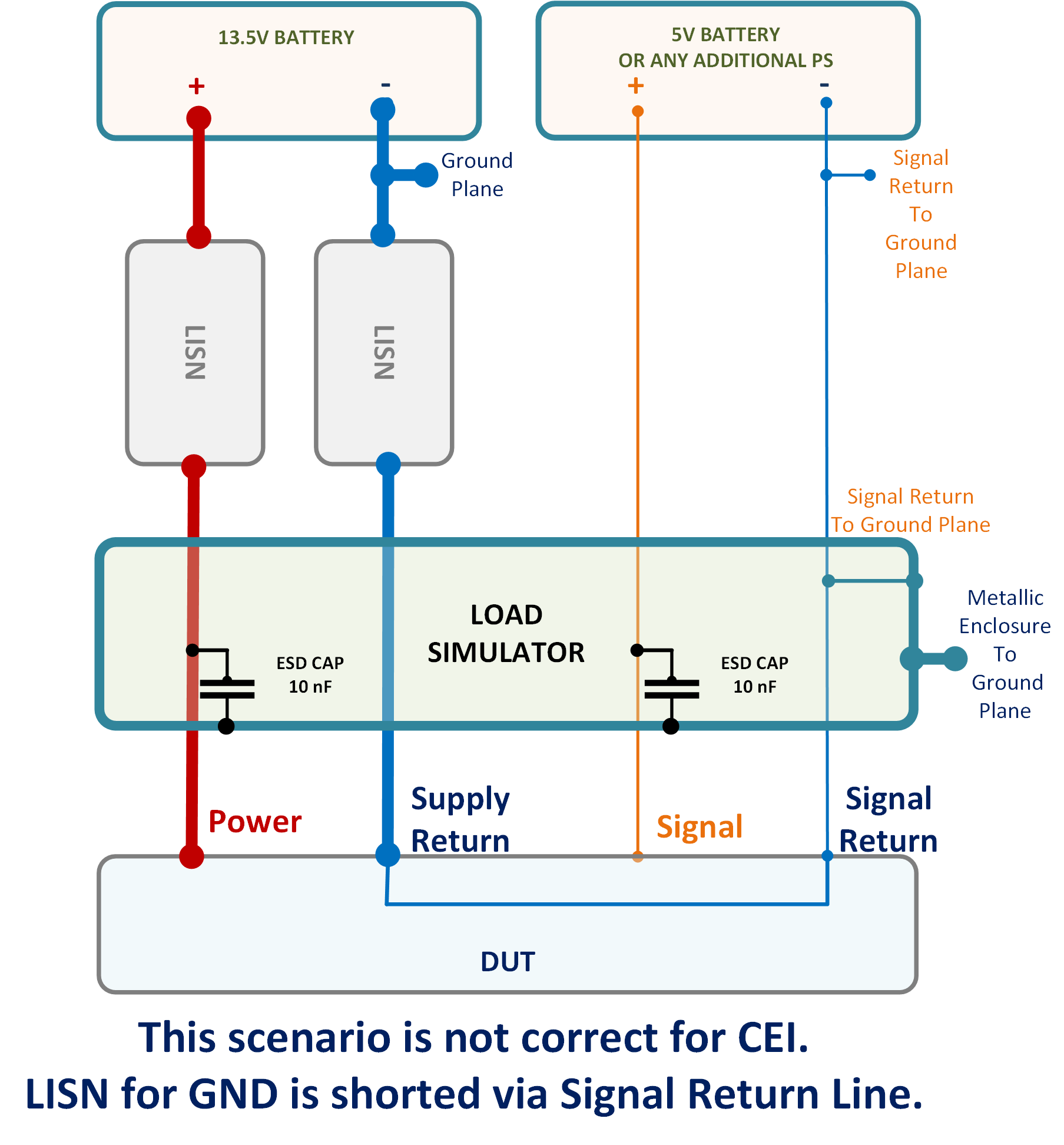

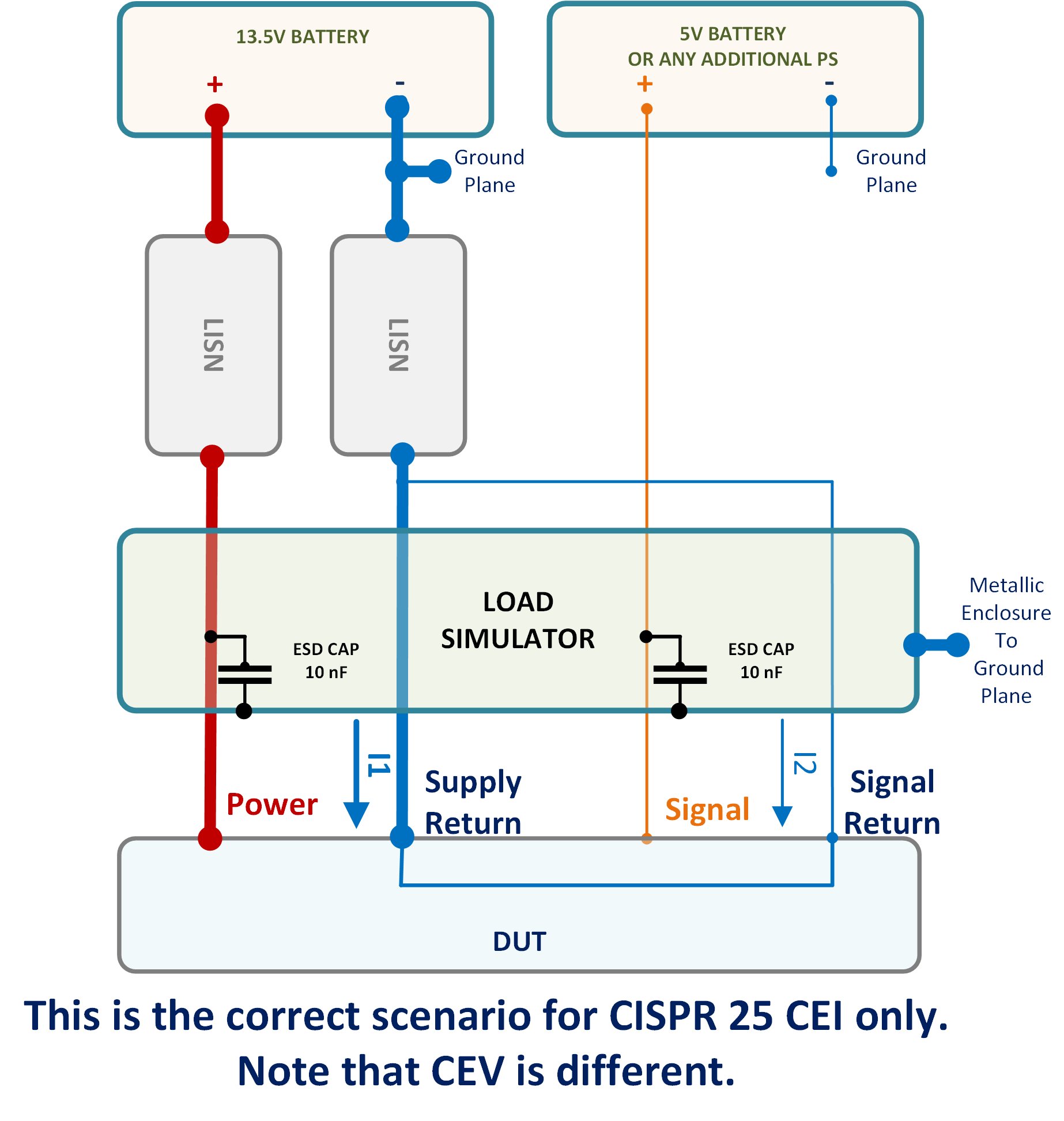

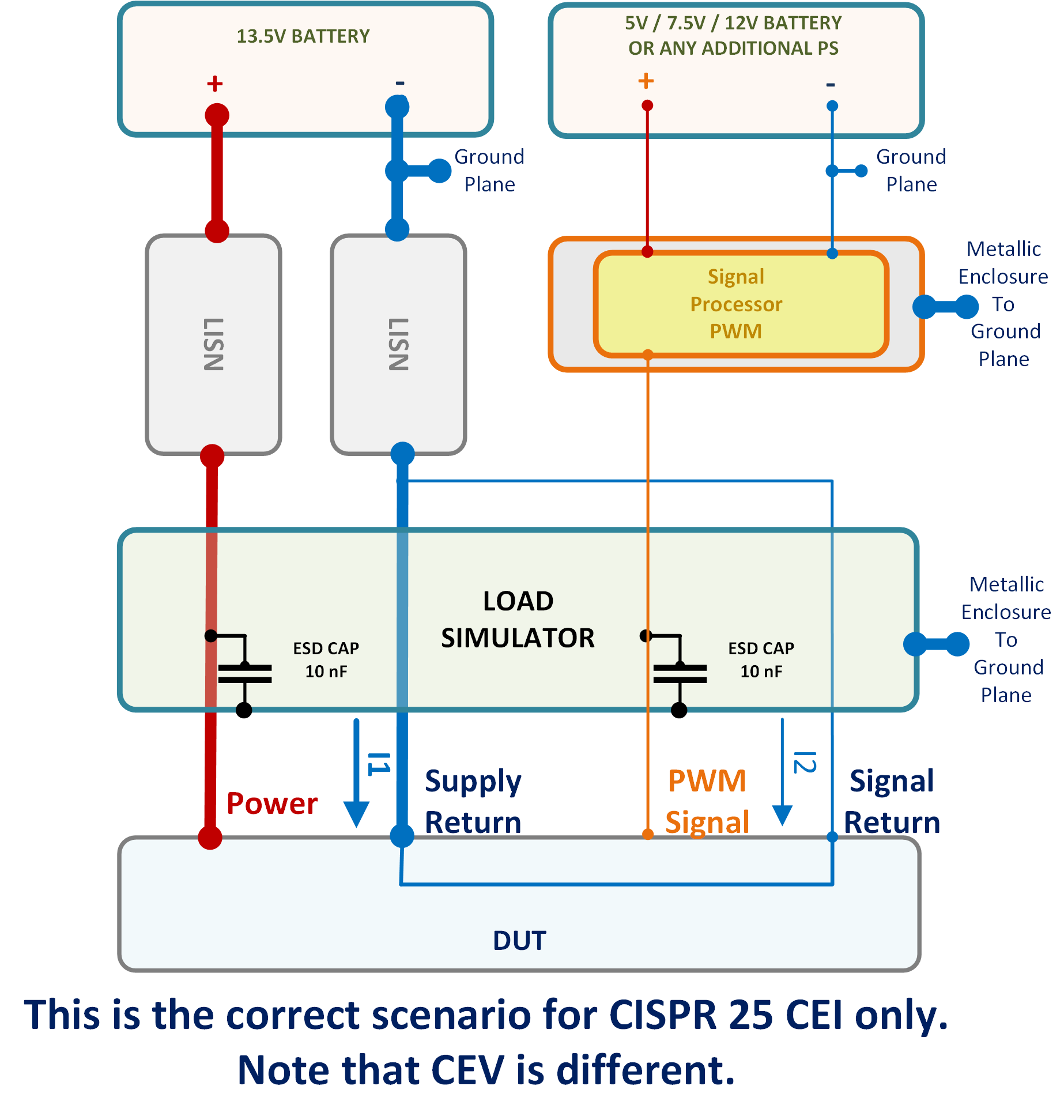

First of all you have to show the LISN in your EMC Test Plan block diagrams. The way the LS is connected is not identical for each CISPR 25 test method. I will never use a Load Simulator unless is no other way around or I would want to turn it into a RF filter box. Examples of CEI good and bad setups are shown below:

CEI WRONG CONFIGURATION

CEI GOOD CONFIGURATION

To clarify how a PWM maker is connected:

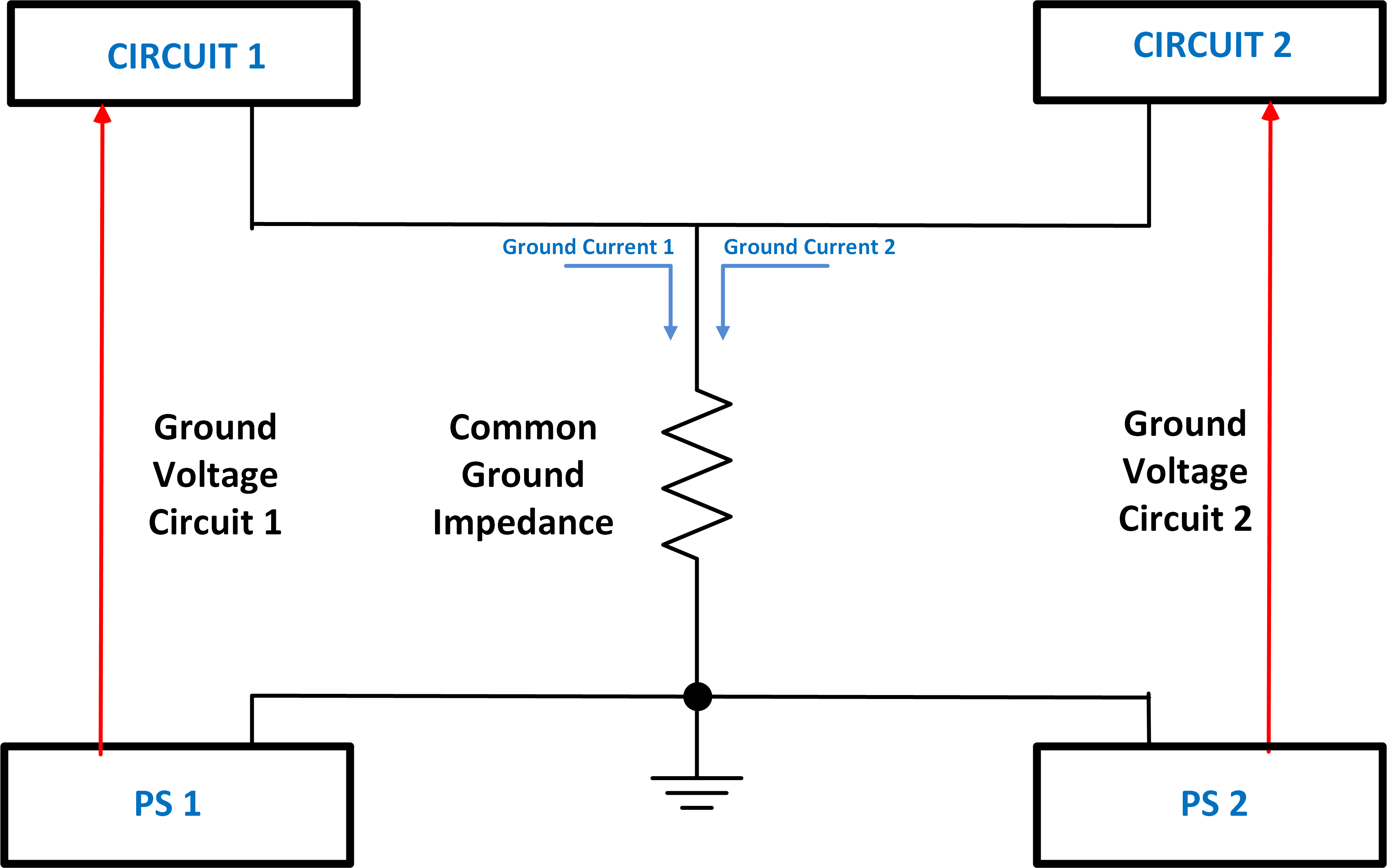

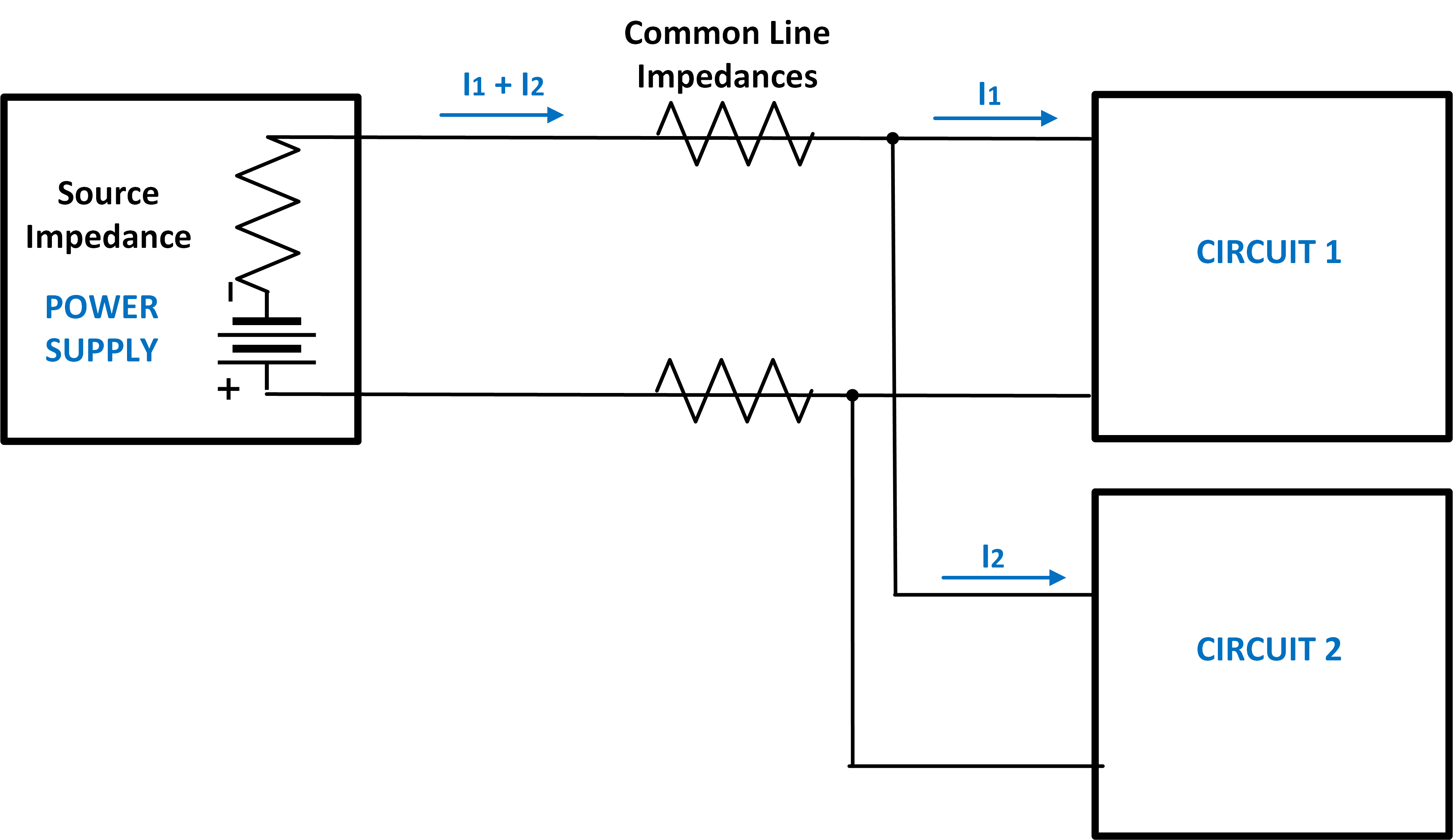

From EMC compliance perspective the goal is to avoid as much as possible common line impedances:

Christian Rosu

2021-04-13

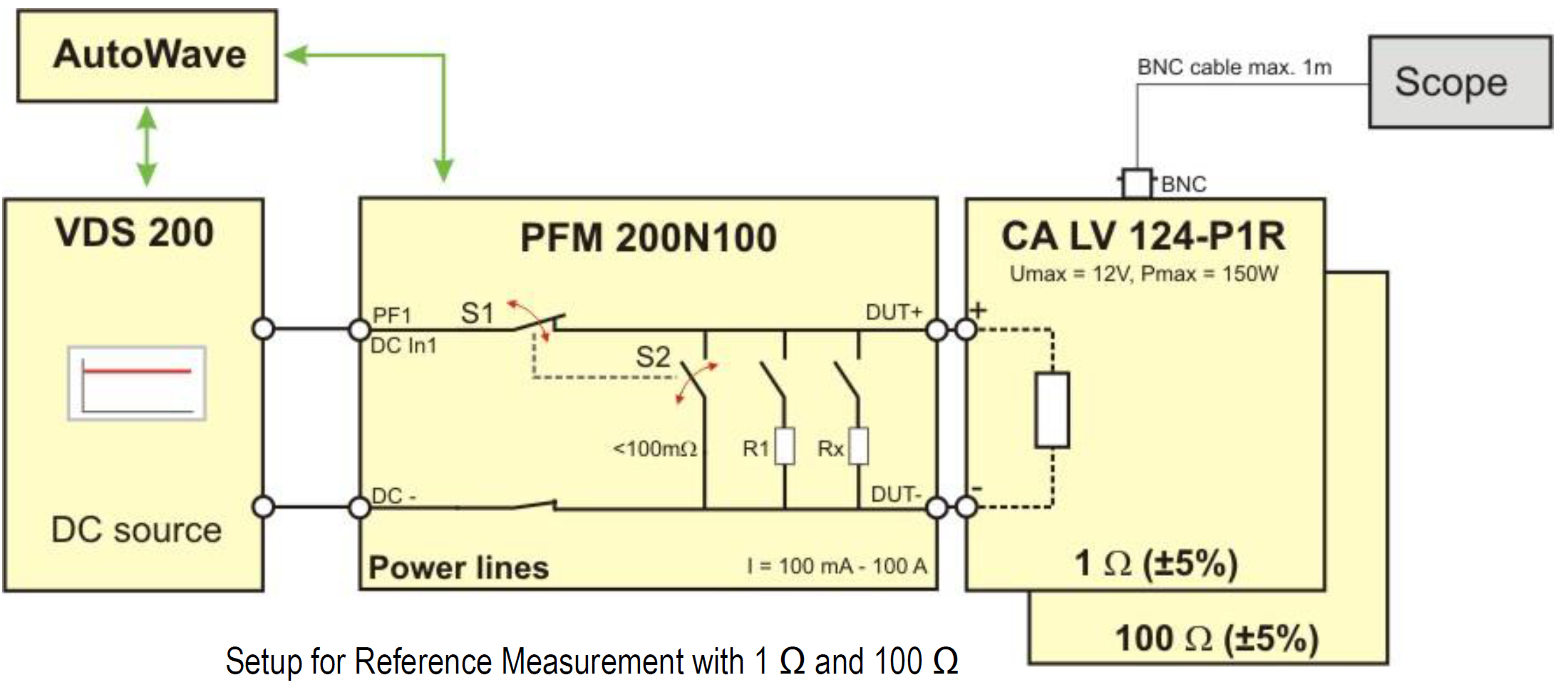

In EMC "dropout" means Battery drops to 0V. FMC1278R3 (CI 260) is an example of various combinations of such battery voltage dropouts. The problem is that no automotive battery can really drop its output to 0V for say 5 seconds as well as for 50 ms without to blowout a fuse.

Therefore the only way to simulate correctly a “battery drop to 0V” is to disconnect DUT's B+ line from battery. The test equipment offers such capability to momentarily disconnect the battery during “voltage dropout” simulating a “0V” like condition, practically no current through supply lines to DUT.

This involves the use of PFM200N + VDS200Q + AutoWave to generate the CI 260 type of pulses. PFM200N acts like a very fast switcher disconnecting its output from DUT. So far only FCA (CS.00054) figure it out to ask “open condition” during “0V” battery voltage dropouts.

In EMC we use the wording “voltage dip” to describe a momentary battery voltage drop (e.g. 4.5V) below minimum supply voltage (e.g. 9V). Obviously in this scenario the Battery B+ line is not disconnected from DUT during the “voltage dip to 4.5V” of 100ms.

Christian Rosu Feb 17, 2021